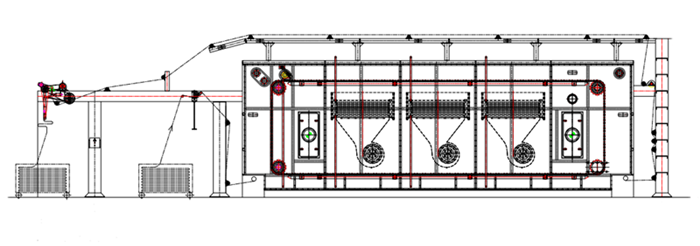

Loop Steamer

Application

This machine is suitable for various kinds of fabrics for steaming fixation color after printing, baking after pigment printing, such as natural fiber, synthetic fiber, chemical fiber and blended woven fabric, knitted fabric, non-woven fabric. It’s suitable for all kinds of dyes. Fabric weight range is 50~800g/m2.

Technical Parameters

1. Mechanical width: 1800~3600 mm

2. Capacity: 140~420mm (Adjusting variable: 70m/section)

3. Fabric feeding mode: front feeding, front outlet, single width, single layer

4. Machine speed: 10 ~80m/min.

5. Loop length: 1.25m~2.5m, regulating ratio: 1:2

6. Steaming time: 4~70min (depend on content and fabric speed)

7. Min. pressure of steam supply: 0.3MPa

8. Technology and temperature: Saturated steam 100℃; low temperature superheated steam 115~150℃; high temperature superheated steam above 150~180℃; hot and dry air above 150~180℃

9. Range of application: dual use of high temperature and low temperature (reactive process, disperse process, discharge printing process, acid process).

Contact:Jennifer Yin

Tel:+86-18168890996

Email:jennifer8992@hotmail.com

Add: West Yanyu Road No.33, Huishan Dist., Wuxi city, P.R. China Post Code: 214000